| This animation of the hot wire cutting process is a typical example from our Plastics Module. It is one of 27 animations describing polymers and plastics forming processes. Text, graphics and animations are used to help students to understand and to learn. Our software contains HTML and PDF versions of these technology notes. |

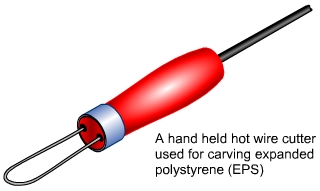

Cutting Expanded Polystyrene with a Hot Wire Cutter |

||

Hot wire cuttersA hot wire cutter may be used to cut and shape It is possible to cut other foams with a hot wire cutter but because of the highly toxic chemicals given off when other foams are heated, it is prohibited to do so. Only expanded polystyrene and extruded polystyrene may be cut with a hot wire cutter in schools. |

|

|

Hot wire cutters consist of a nickel chrome alloy (Nichrome) resistance wire held between two electrical connectors. A current is passed through the resistance wire, causing it to heat up. The amount of current passing through the wire is controlled so that the wire heats up just enough to allow the hot wire to pass through polystyrene. Thin resistance wire is held taut between two connectors. Thicker resistance wire has rigidity and so does not need to be held taut. A rigid resistance wire may be shaped to any desired profile and used to carve shapes and to cut architectural mouldings. Computer numerically controlled (CNC) hot wire cutters are used to create a vast range of polystyrene products including signs, mouldings and carved figures. Safety Notice

CLEAPSSPlease refer to CLEAPSS, Model Risk Assessments for Design and Technology in Secondary Schools and Colleges, Part 1.057COSHH Regulations. |

||